4 Layer PCB Assembly

- Home

- 4 Layer PCB Assembly

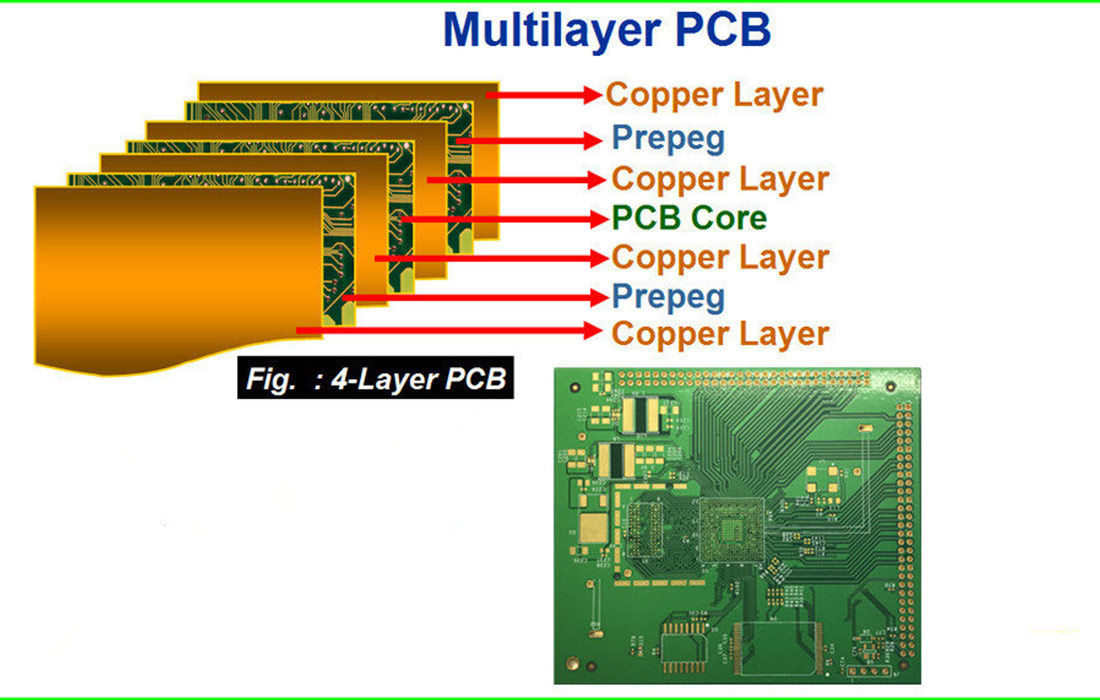

4 Layer PCB Assembly

OEAS stands as a premier player in the electronics sector, delivering top-tier 4-layer PCB Assembly services designed to cater to a wide range of manufacturing requirements. With our rich experience and unwavering commitment to quality, we excel in providing dependable and efficient solutions for 4-layer PCB Assembly. Whether your needs are for prototypes, small production runs, or large-scale manufacturing, our state-of-the-art facilities and expert team guarantee meticulous execution and strict adherence to high-quality standards.

Our commitment to excellence is not limited to the manufacturing phase; it spans every stage of our 4-layer PCB Assembly services. From the initial design consultations to the final delivery of the product, we focus on precision and reliability to ensure that every project surpasses expectations. Choose OEAS for your 4-layer PCB Assembly requirements and witness our dedication to delivering superior quality, efficiency, and innovation in the field of electronic manufacturing.

4 Layer PCB Fabrication Capability

| Provide free DFM Checking, and We can suggest 4 layer PCB stack-up | |

| Copper Thickness | Max to 6 oz inner copper, 12 oz outer copper |

| Min Hole | 0.15mm by mechanical drilling, 0.1mm by laser |

| Board Thickness | 0.4mm – 6.5mm |

| Surface Finish | Immersion gold, Immersion Silver, Immersion Tin, Hard Gold, OSP |

| Soler Mask | Green/Yellow/White/Black/Custom |

| Silkscreen | White/Black/Yellow/Custom |

| Accept 4 layer PCB with Blind or buried Via Hole | |

| 100% Testing | |

| 100% on-time delivery | |

Advantages of 4 Layer PCB

- Improved Signal Integrity : Improved signal integrity ensures that electronic signals transmit without distortion or loss, maintaining their integrity across the entire system. This leads to better performance and reliability of electronic devices, especially in high-speed data applications where precise and clean signal transmission is crucial.

- Reduced Electromagnetic Interference (EMI) : Reduced electromagnetic interference (EMI) is essential for the smooth operation of electronic devices, as it minimizes the disruptive impact of external and internal electromagnetic fields. Lower EMI levels prevent signal degradation and data loss, ensuring that devices can operate without interference from other electronic components or external sources.

- Increased Component Density: Increased component density allows for more electronic components to be packed into a smaller space, leading to more compact and powerful devices. This is particularly beneficial in modern electronics, where space is at a premium, and performance demands are high.

- Better Power Distribution : Better power distribution ensures that all components within an electronic system receive the appropriate amount of power, leading to improved performance and efficiency.

- Enhanced Reliability: Enhanced reliability in electronic systems means fewer failures and longer operational lifespans for devices. This is achieved through improved design, higher-quality components, and better manufacturing processes.

Recommended Services

Recommended Services

ORDER YOUR PCB NOW

Innovating Circuits, Empowering Futures.